Startup Saturday: 3D printing, A physical reality from digital design

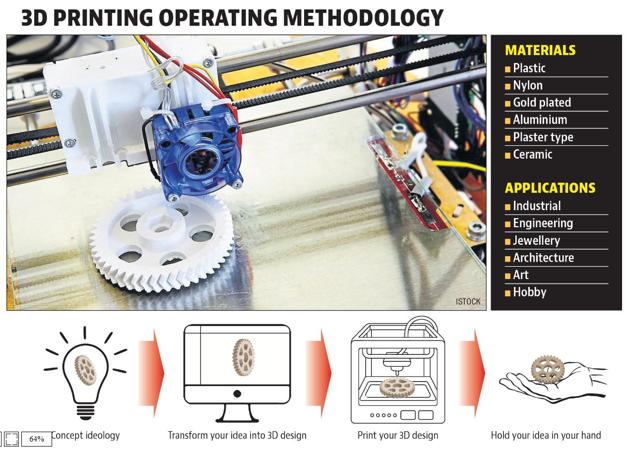

There is a first-mover advantage. Then there are first-mover learnings. Prima facie, the 3D printing business in Pune has more of the latter. HT talks to two young 3D printing startups busting the networks to get that advantage. That is, of course, once they explain how 3D printing works

Conquering limitations of tech’s new dimension

About

“ I was always interested in technology and manufacturing. I would read a lot and often visit factories as manufacturing always fascinated me. Those were the days when 3D printing had just been introduced. Completely taken over by the subject, I decided to dive into it”.

Early days

“I lauched my own company Form3D solutions in 2015. I initially had ideas of getting into the business of corporate gifting and artificial jewellery or work with architests. But that did not take off.

Param learnt that for making accessories, the materials used in 3D printing was not suitable. Plastic - Acrylonitrile butadiene styrene (ABS) the material used does not give the finish and detailing required for such items. He realised the limitations of the technology.

“We were making small things and struggling with the finishing.”

Something that even Param realised was switching to making prototypes for the auto component and electronics industry.

Buiding the business

“Our business model now is to provide end-to-end solutions to companies. Right from the ideation stage, the design on the computer, the 3D printable file to making prototypes, we offer all these services.

“In fact, we even handle the vendors for them. If a client wants about 50 pieces to test in the market then we do that as well. Small quantities make 3D printing viable. It’s the large quantities that are unviable.

Future

“The first is scale. How do you scale it up? At some point 3D printing becomes unviable. That’s the nature of the technology. The second is that if the printers are not used for a week or two then things will go wrong. The technology still has to mature. Then you have every Tom, Dick and Harry who will have a 3D printer, but what creates a professional finished product is the 3D printable software. Anything won’t work. But customers often see such poor quality products that give 3D printing a bad name.

“About 10 years back Samsung had introduced the android phones with touch screen. At the same time, some Chinese company made a cheap imitation. People used the cheap stuff and gave touch phones a bad name. The same thing is happening with 3D printing. The other issue is the costing. If your machine is not loaded fully you will end up spending a lot more. Nevertheless, the future looks bright.With an initial investment of Rs 10 lakhs, last year our turnover was Rs 25 Laths and this year we expect it to grow to 40 Lakhs plus.”

A lower cost tech compared to the old way of casting

About

“I was working as a mechanical engineer at Thermax. My friend from Australia, Kiran Hurkadli who was already into 3D printing, introduced me to the ‘marvels’ of this technology. Since we both are mechanical engineers, we got fascinated by this technology and sought to learn more. We took a trip to China to see how these machines worked. And we came back fully convinced of its capabilities.”

Early days

“Our fathers set up the company ‘Spectra 3D’ to help us realise our dreams. When we started we were very clear that we would focus on the automobile, electrical and electronics industry for their prototyping needs. But the problem with our clients was that most of them were not aware of the benefits of 3D printing. I realised that I had to educate the people first.

“ Though my friend in Australia is running a similar business which is flourishing, it is on account of high labour costs. The situation is very different. labour is cheap here. But what these companies don’t realise is that 3D printing is cheaper for making prototypes that often need several versions.”

Building the business

Let’s say that a company wants to make a new design remote control. Earlier this would be very expensive to do with traditional manufacturing. But what we need is the design on which a 3D file is created. This is designed around the PC board. And a newly designed remote is ready. Want to make some changes after it’s printed? No problems.

With a 3D printer, you can make several versions at a cost much lower compared to the old way of moulding and casting. This is exactly what most companies do not understand.

“When they hear the cost of material and other related details, they feel it is too expensive. But when you compare it with the cost of making a mould, this is very cheap. When we go to meet a client, most of our time we spent on educating them about the benefits of 3D printing for making prototypes. After all that, then about 20% -25% people get convinced.”

Future

“ I wish more big companies get involved in 3D printing and would educate their staff about it. There are some like Thermax, Atlas Copco who ask us to make prototypes for them. Of course, we have non-disclosure agreements (NDA) and are very careful about not disclosing their patented technologies. But such companies are very few. I wish more would do so. There are some companies who have invested in 3D printers like Kirloskar Brothers, M&M but they are in it to avoid technology leakages. That is a very sensitive topic you see,” Rohan added

4D challenges that 3D industry faces

“The first is scale. How do you scale it up? At some point 3D printing becomes unviable. That’s the nature of the technology. The second is that if the printers are not used for a week or two then things will go wrong. The technology still has to mature. Then you have every Tom, Dick and Harry who will have a 3D printer, but what creates a professional finished product is the 3D printable software. Anything won’t work. But customers often see such poor quality products that give 3D printing a bad name,” says Param

People are slowly coming round to this technology. Param has different plans. “Though we have not yet touched a crore in turnover yet (it’s about 30 Lakhs) we are happy with the way things look. I intend to expand our design service that can create good 3D printable files. And I also wish to get into manufacturing 3D printable materials. That looks like a need that is not yet touched.” Rohan added